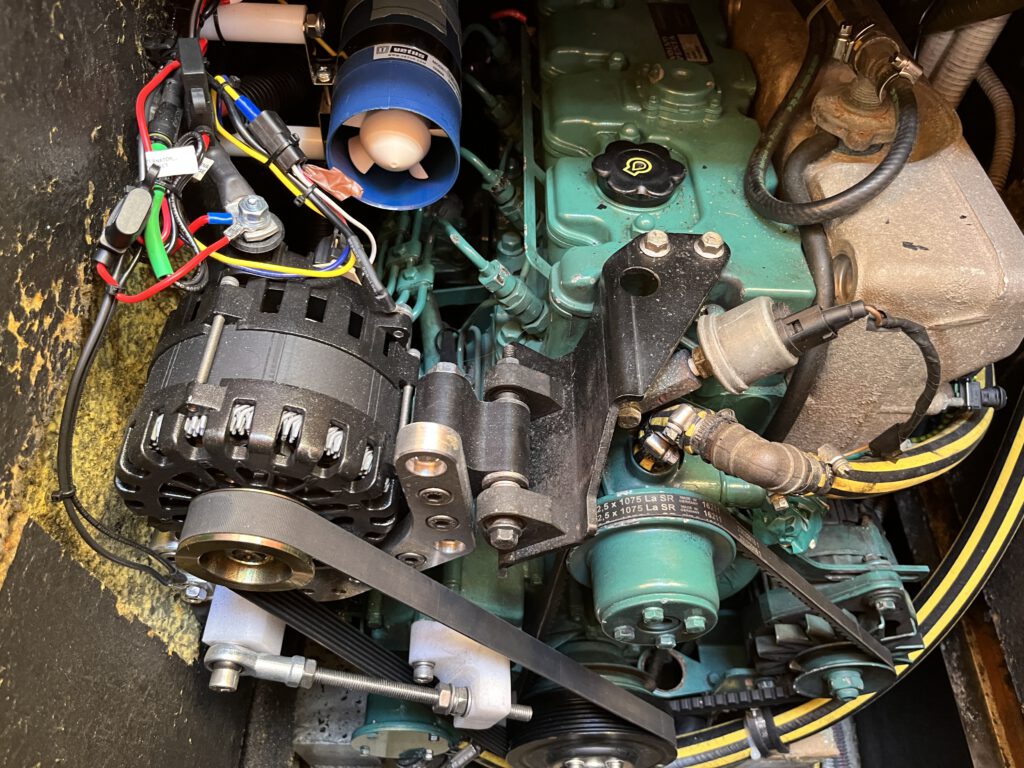

When I decided to install a Balmar XT-250 alternator on my boat engine, it was primarily to efficiently charge the 11kWh LiFePo battery bank. The alternator is regulated by a Wakespeed regulator, which allows it to deliver up to 2.5kW while running, providing the necessary power for the battery bank. Check previous post.

One great feature of the setup is that the regulator waits 60 seconds after engine startup before ramping up the charging current. This delay ensures that the engine isn’t stressed during warm-up, allowing it to reach operating temperature before the alternator ramp in.

The K6 Drive Belt Issues

The alternator is driven by a K6 belt that’s tensioned using a screwed tensioner, which adjusts the position of the alternator. However, one issue we’ve encountered is that the belt tends to jump off the alternator pulley during engine cranking or when idling.

Initially, we tried increasing the belt tension, but this only made the problem worse. After further investigation, we discovered that improving the alignment between the alternator pulley and the crankshaft pulley reduced the frequency of the belt slipping off. However, the problem persisted, particularly due to the strong oscillating forces generated by the engine during cranking and starting.

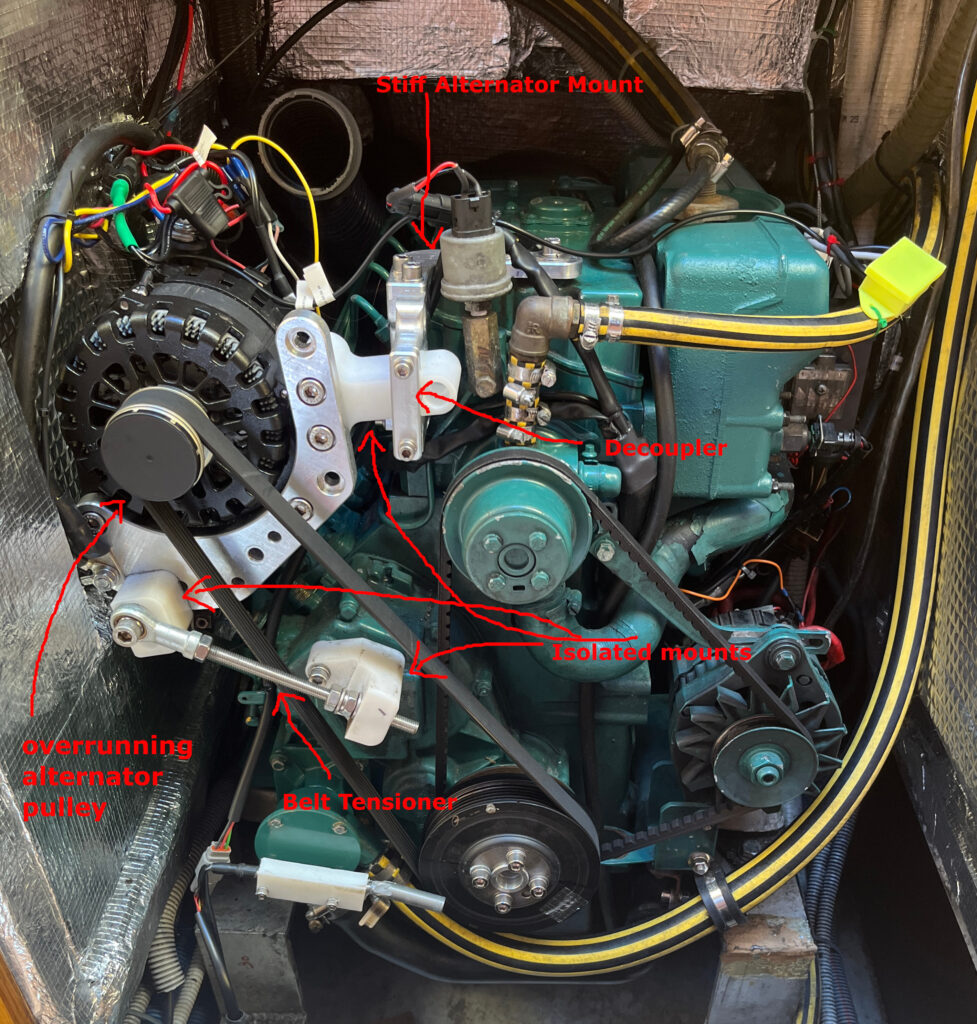

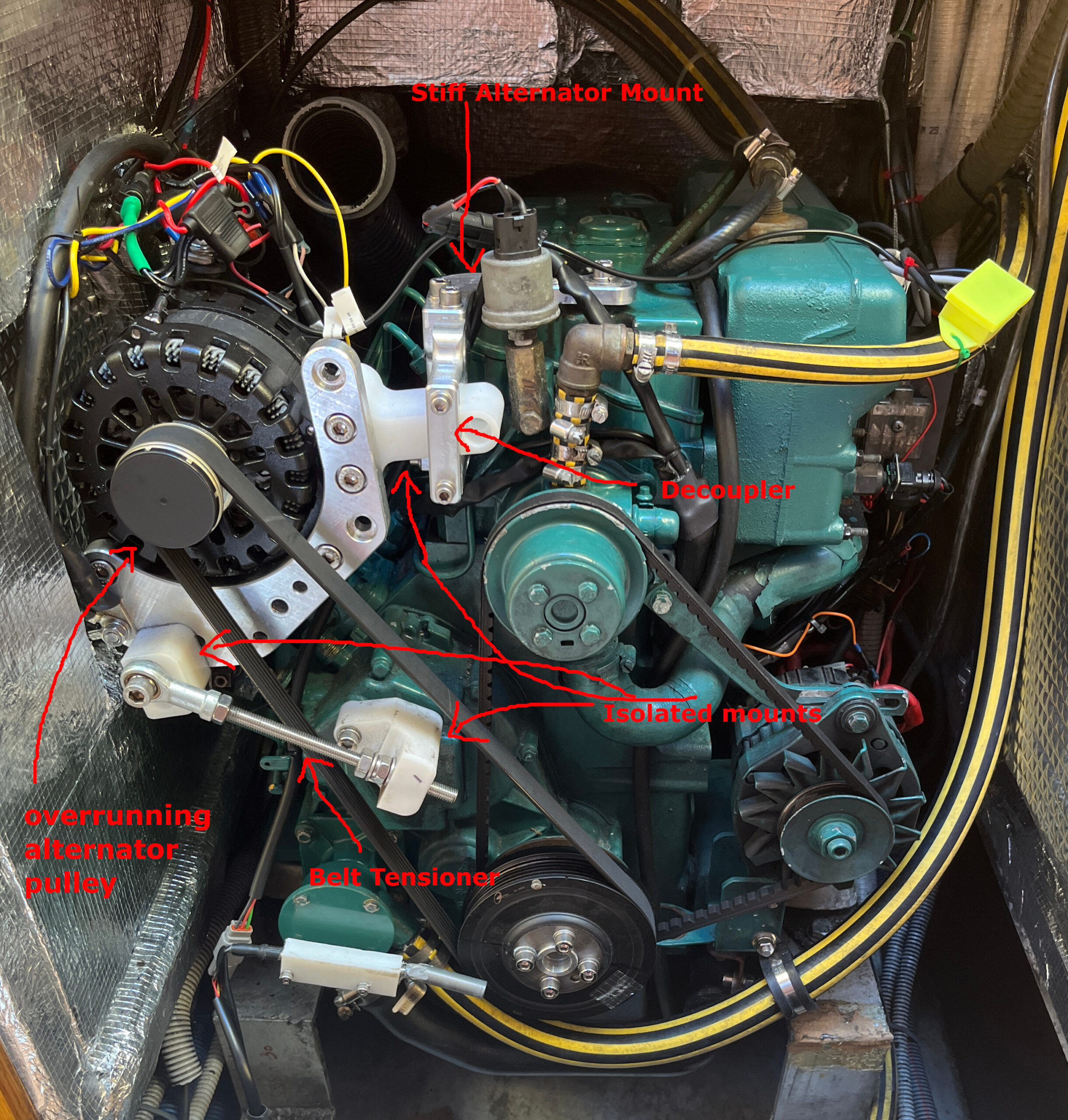

Another contributing factor is the alternator mount, which isn’t as stiff as it should be, leading to additional movement between the two pulleys. This flexibility causes the belt to misalign under the strain of engine vibrations.

Solutions for belt jumps

Stiffer Alternator Mount

To solve the persistent belt jumping issue, we decided to replace the original steel sheet mount with a custom full aluminum mount for the alternator. This upgrade has made a significant difference. The aluminum mount is much stiffer, reducing the flex and movement that occurred with the previous setup, especially during engine cranking and idling.

Overrunning Alternator Pulley

The most complex solution is to install an overrunning alternator pulley. This part is very common in automotive engines but unfortunately, Balmar doesn’t provide an overrunning pulley specifically for their alternators, and the XT-270’s shaft design doesn’t easily accommodate this type of pulley, making it a more challenging project to implement.

The overrunning alternator pulley is an upgrade from the traditional fixed belt pulley found on alternators. Its key feature is an overrunning clutch, which helps dampen the vibrations caused by the crankshaft’s cyclic irregularities. By allowing torque to be transmitted in only one direction, this pulley reduces the stress on the belt and alternator, providing smoother operation and extending the life of the system.

We mounted the RIDEX 1390F0038 Generatorfreilauf on the alternator shaft. With a width of 39.5mm, it’s been a great fit for the setup.

🚀Conclusion 🌊

After a full season of sailing with both solutions in place—the full aluminum alternator mount and the overrunning alternator pulley—we’ve finally won the battle with the engine belt. No more peeking into the engine room every five minutes to see if the belt has decided to go rogue! The new setup has been a game changer. It’s eliminated the constant “is the belt still there?” paranoia and given us a much smoother, hassle-free sailing experience.

![Read more about the article What is the required amount of electric power needed for cooking on a boat? [measurements]](https://sv-tatooine.com/wp-content/uploads/2023/03/Ente_Kloese_Rotkohl-300x174.png)