Working on the centerboard of an aluminum lifting-keel boat is one of those jobs that looks absolutely terrifying… right up until you take a deep breath, make coffee, and break it down step by step.

At least, that was my experience.

On SV Tatooine (Alubat Ovni 435), we had to remove the centerboard (light version — no ballast) for inspection, cleaning, and refinishing. And since proper documentation is… let’s say… mysteriously rare, I decided to share exactly how we did it.

Because here’s the good news: This job is totally doable — even if you don’t have a big team of muscular shipyard superheroes.

We certainly didn’t.

This procedure applies to the light (non-ballasted) Ovni centerboard.

Secure the Centerboard in the Upper Position and fix it

First, bring the centerboard fully into the upper position.

From outside the boat, mechanically block it so it cannot drop.

Removing the Side Covers (aka Sikaflex Hell)

Next step: remove the screws holding the access covers.

Sounds easy.

It was not.

Alubat — in their great enthusiasm for things staying permanently in place — had applied what can only be described as industrial quantities of Sikaflex.

Result? Absolute pain in the ass.

In theory, the middle threaded holes are meant for inserting screws and using them as pullers to extract the cover.

Good idea. The problem on our boat was simple:

the plate is too thin

the Sikaflex bond is extremely strong

and the threads… well… they gave up before the glue did

Remove the Hydraulic Cylinder Pivot Pins

Remove the Hydraulic Cylinder Pivot Pins

Once you finally win the battle against the Sikaflex and remove the covers on both sides (yes… all six covers), you can move to the next step.

Tools used:

Once the pivot pins are finally out, first, pump the cylinder further up using the hydraulic system. This gives you the extra clearance needed.

At this point, the cylinder should come out.

Before going any further, the hydraulic lines have to be disconnected.

And this is the moment where things can get… splashy.

Here is what I strongly recommend — from experience:

- Have an empty canister ready

- Keep rags within arm’s reach

drilled a hole in the top of the centerboard

installed a strong lifting ring

used this ring as the external support point

This allows the board to remain safely suspended during the next operations.

🏗️ Build Yourself a “Budget Shipyard Crane”

Since we were clearly missing a team of heavily tattooed shipyard professionals, we did what any determined Ovni owner would do:

With the wooden crane standing the next step was to attach the chain pulley to your new centerboard ring.

Drive Out the Main Centerboard Pivot Pin

With the hydraulic cylinder removed, the last thing holding the centerboard in place is the main pivot pin.

In theory, you might suspect a clever locking mechanism. There is no catch. It’s just… tight.

On SV Tatooine, the procedure was beautifully simple and slightly athletic.

Asolid pin drift + a HUGE hammer … understanding of mass inertia.

Lowering the Centerboard

With the main pivot pin finally out, the centerboard is now free.

Well… almost free.

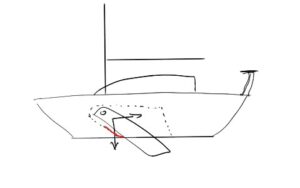

At this stage, you can begin to lower the centerboard, but — and this is important — it does not come straight down.

On the Ovni 435, the correct movement is:

- downwards

- and slightly toward the aft (back of the boat)

To free the board cleanly, you must carefully guide these bushings so they pass along the longitudinal sliders inside the centerboard trunk.

Check Your Ground Clearance

Here is something that is very easy to underestimate… until you are lying under the boat with a centerboard that refuses to come out.

On SV Tatooine, the boat was initially sitting too low on its berth.

To finish the job properly, we had to ask the yard to bring in the port lift and raise the boat higher.

When the boat was placed back on the berth, we specifically asked the yard operator to set her on a higher berth.

The Satisfying Results 🎉

when reinstalling the centerboard

👉 we did not want to depend on the lift again-

With the centerboard finally out , we could properly inspect the surface.

The board was sandblasted to remove old coatings and oxidation by a professional. Then they filled the uneven areas with epoxy, fairing the surface. and applying primer for protection.

When the centerboard was delivered back to the boat, as good as new, we secured it with lines on deck from both sides. This allowed us to suspend it safely and apply the antifouling in comfortable working conditions.

Afterward, those same lines — led to the winches — became extremely useful. They gave us precise control to guide and position the centerboard carefully back under the boat for reinstallation.

Because we couldn’t remove the longitudinal gliders, reinstalling the centerboard required a bit of creative gymnastics.When putting the board back in, we first had to lift it carefully and guide the board past the gliders before installing the new pivot-pin bushings.

Let’s just say… this is where small hands become a strategic advantage.

It’s fiddly, slightly awkward.

Lift up an to the front of the boat.

This construction helps to move the centerboard forward in its truck.

Reinstall the Pivot Pin and Take Care of the Hydraulic Piston

Reconnecting and Bleeding the Hydraulic Cylinder

Before placing the piston back in position, we reconnected and filled the hydraulic circuit first. This makes the final installation much cleaner and avoids fighting trapped air later.

Our procedure:

Place both hose ends into a container filled with glycol water.

Pump with the handle in position down, then repeat with the handle in position up.

Keep both hose ends submerged in the glycol water.

👉 Continue until no more air bubbles come out of the hoses when the handle is in the neutral (middle) position.Tighten upper hose fitting on the cylinder.

Put the handle in position up.

Pump until the cylinder reaches its end stop.

👉 You will feel the handle become firm.Switch the handle to position down and pump again.

👉 Fluid should come out of the remaining hose without air.Return the handle to neutral.

Tighten the remaining hose fitting on the bottom of the cylinder.

Put the handle in position down.

Pump until the cylinder reaches the end stop with the rod fully extended.

👉 Again, the handle will become firm.Perform two complete full strokes, carefully switching the handle position each time.

Reinstalling the Hydraulic Cylinder

Once the hydraulic system was properly filled and bled, the next step was to bring the piston into the fully retracted position.

From our experience on SV Tatooine, the easiest method was:

Position the cylinder in the trunk

Fix the lower end of the piston first with its pivot pin

Then pump the system slightly to move the upper eye into position

Align carefully in front of the upper hole

Insert the upper pivot pin

That's it! now test it.

Once everything was back together, we performed a full functional test of the system.

On SV Tatooine, we cycled the centerboard several times fully up and fully down, watching carefully for, smooth movement, no abnormal noise, no hydraulic loses.

Don’t Forget the Zinc

As a last step, we installed a zinc anode at the end of the centerboard to help prevent corrosion.

Small detail, big importance.

Properly positioned, the anode does not interfere with the full lifting of the centerboard, while providing valuable galvanic protection.

🏁 Final Thoughts

Removing and reinstalling the Ovni 435 centerboard (non-ballasted version) is absolutely doable without a full shipyard team.

Fair winds!

Maria — SV Tatooine ⛵✨